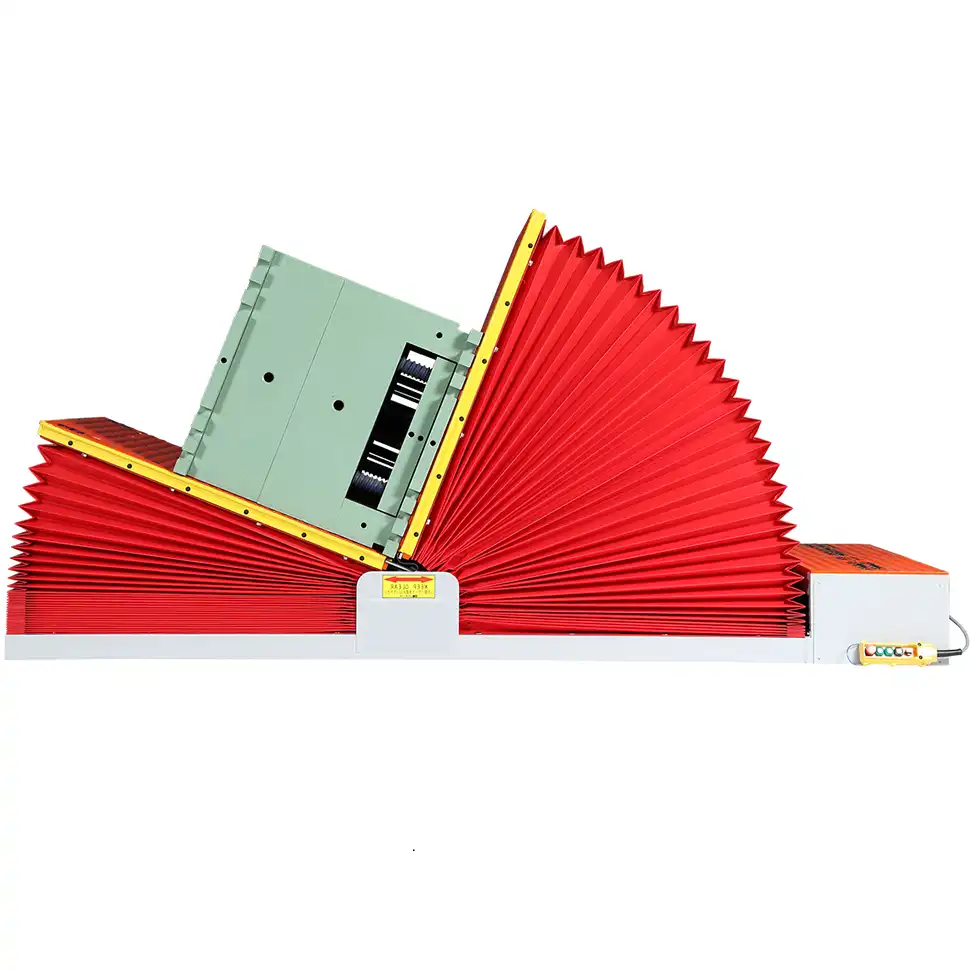

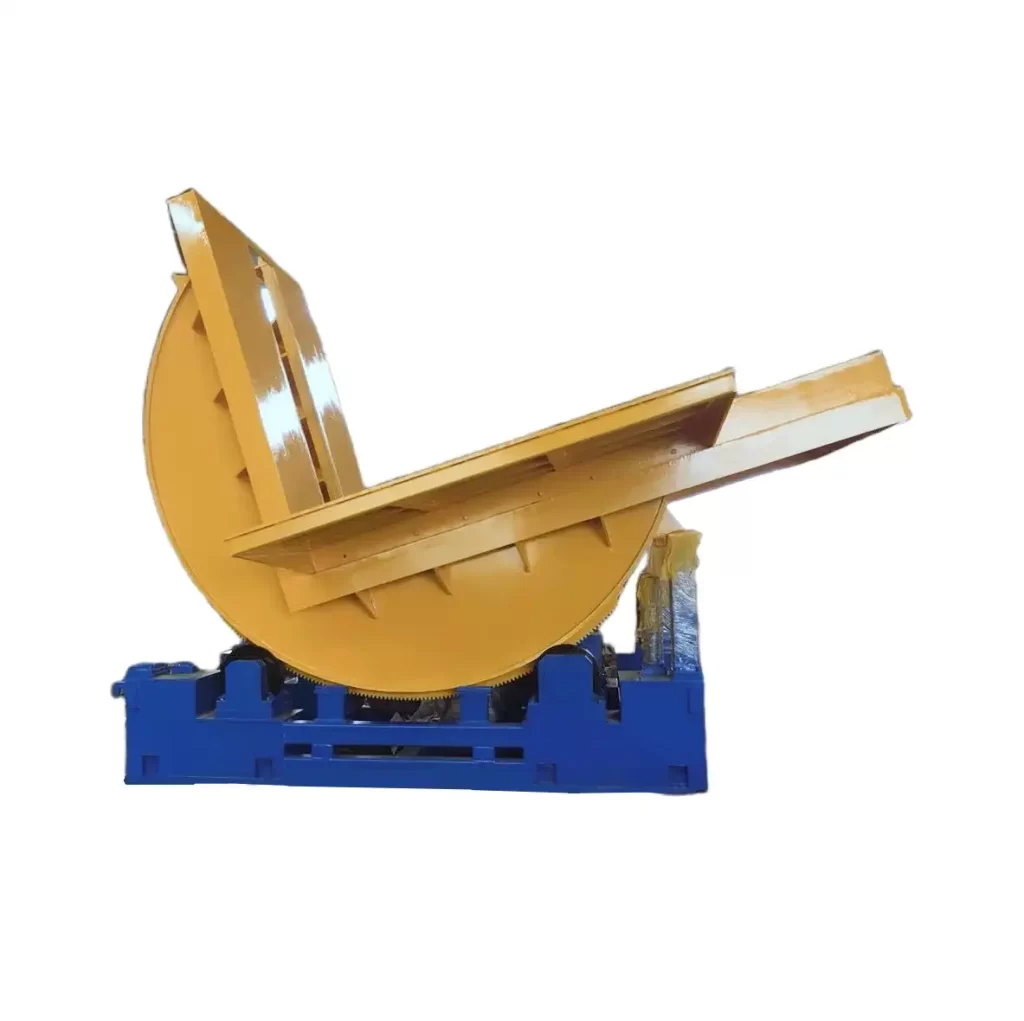

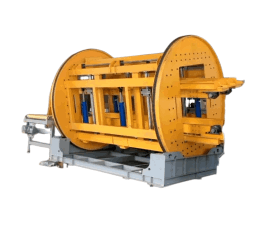

Floor Base Hydraulic Upender

The Floor base Hydraulic Upender/Tilter is designed to rotate heavy objects during operations. It features excellent stability and a robust construction, suitable for managing heavy loads. This machine offers straightforward operation and enhanced safety for the operator. A key benefit of this equipment is its low maintenance requirements.