SAFETY:

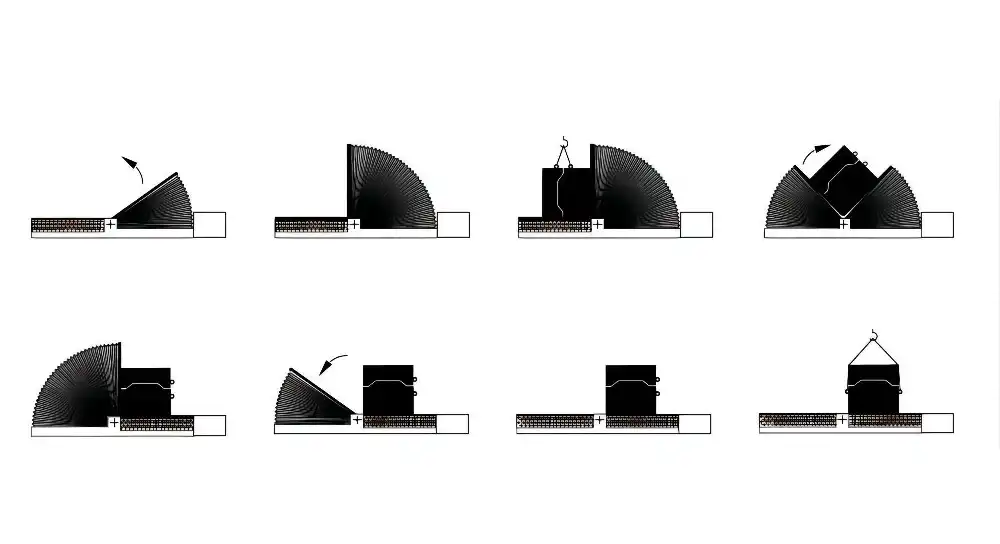

For enhanced emergency response, the flipper is equipped with both an electric limit switch and a mechanical stopper.

It can halt at any angle during operation, even in the event of a power outage.

The tilting speed of the mold is safely controlled by an inverter, ensuring a gradual increase and decrease in speed at the start and end of the flipping process.

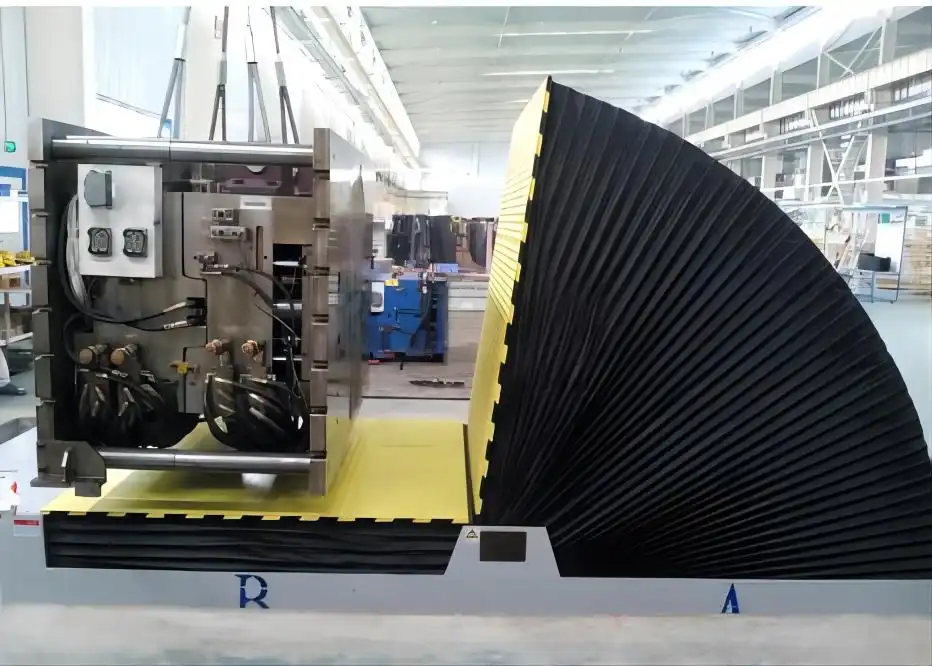

Thanks to its hydraulic drive, the mold is handled smoothly by the flipper, minimizing impact and ensuring safety.

SPACE EFFICIENCY:

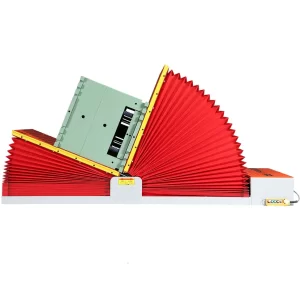

The machine’s compact design requires minimal space, allowing it to be installed in any corner or pathway within the facility.

Both the working table and the hydraulic station are designed for easy maintenance and repair.

The mold flipper machine can be securely mounted on the floor or recessed into a pit, facilitating ground-level handling.