Specifications:

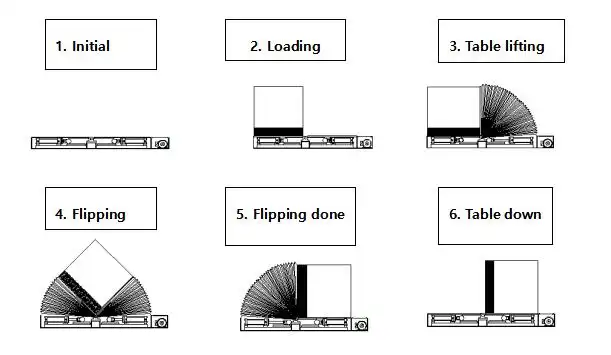

- Capable of 90 or 180-degree mold rotation.

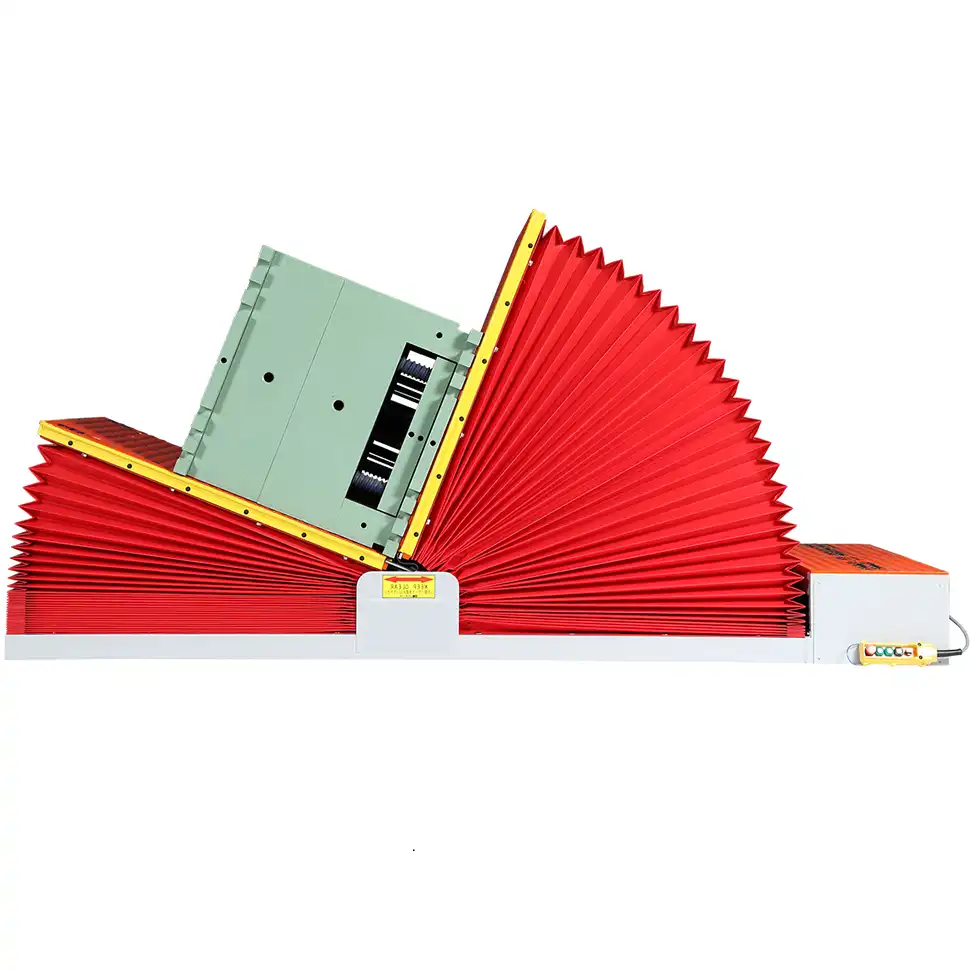

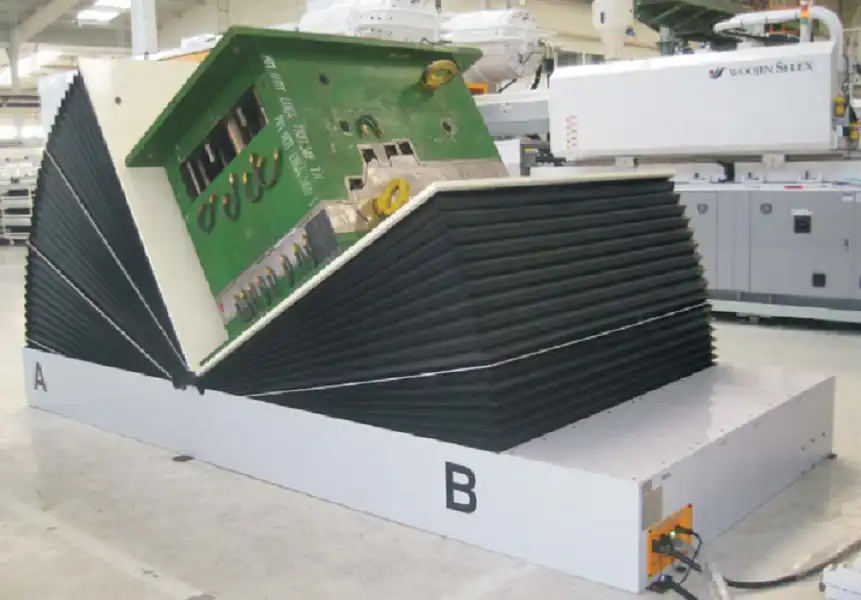

- Sturdily constructed framework.

- High-quality hydraulic system, including valves and cylinders.

- Adjustable rotation speed.

- Features soft start and stop mechanisms.

- Equipped with mechanical and electrical stop blocks for safe operation.

- Operable via control panel or remote control.

- Automatic stopping feature.

- Provides smooth, precise, and vibration-free movement.

- Utilizes two-way back pressure technology.

- Actuation through double-acting hydraulic cylinders on each working table.

- Mold loading options include use of a forklift or crane equipped with a rope.

- Mold unloading can be done using a crane or forklift.

- Control through a pedestal-mounted hydraulic power unit with up-down controls.

Mold flipper table