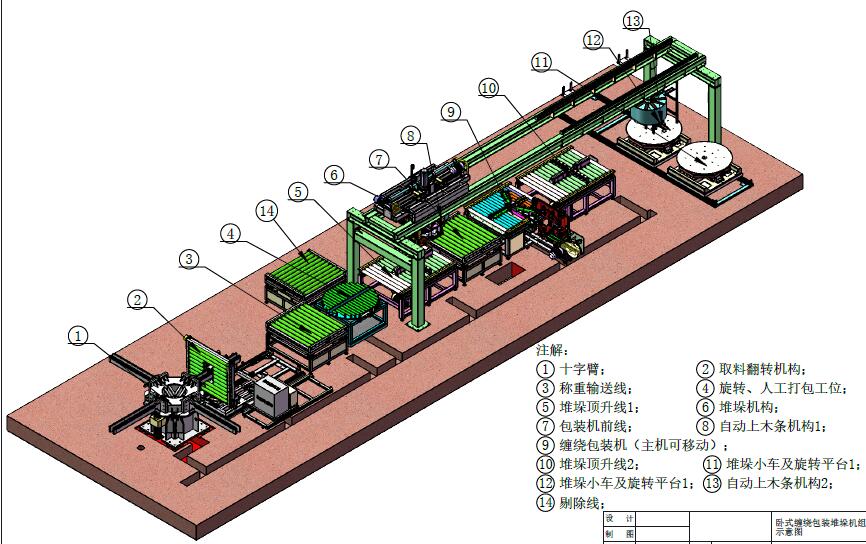

Key Features:

- Automated System: Designed specifically for the efficient handling and packaging of stainless steel and alloy coils, this system integrates various components for seamless operation.

- Integrated Components: Includes crucial machinery such as a coil car, coil downender, coil packing machine, and a stacking system, each playing a vital role in the packaging process.

- Specialized for Stainless Steel and Alloys: The line is tailored to meet the unique needs of processing and packaging stainless steel and alloy coils, ensuring they are handled with precision.

- Secure Coil Transportation: The coil car transports the coils safely to the required station, reducing the risk of damage during movement.

- Efficient Lowering and Positioning: The coil downender carefully lowers the coils onto the conveyor, positioning them correctly for the subsequent packaging steps.

- Protection and Handling: The coil packing machine wraps the coils effectively with suitable materials, providing necessary protection during subsequent handling and transportation.

- Organized Stacking and Storage: After wrapping, the stacking system methodically places the coils on pallets, facilitating organized storage and safe shipment.

- Labor Reduction and Safety Enhancement: This automated line minimizes the need for manual labor in handling heavy coils, thereby enhancing workplace safety and operational efficiency.

- Minimized Human Intervention: By automating the process, the system reduces human error and streamlines operations, ensuring consistency and reducing the risk of coil damage.

- Precision and Consistency: The automated processes ensure that each coil is handled consistently, maintaining high-quality standards and precision in packaging.