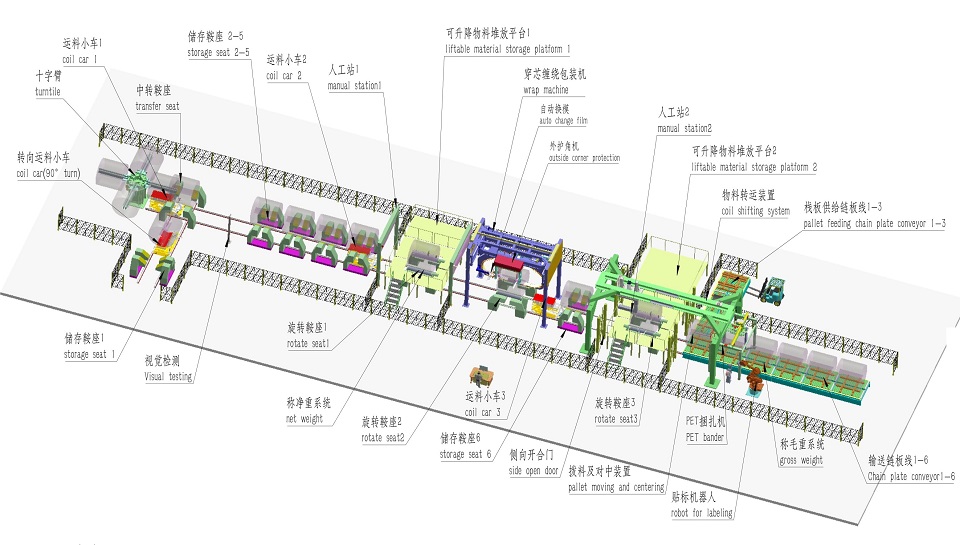

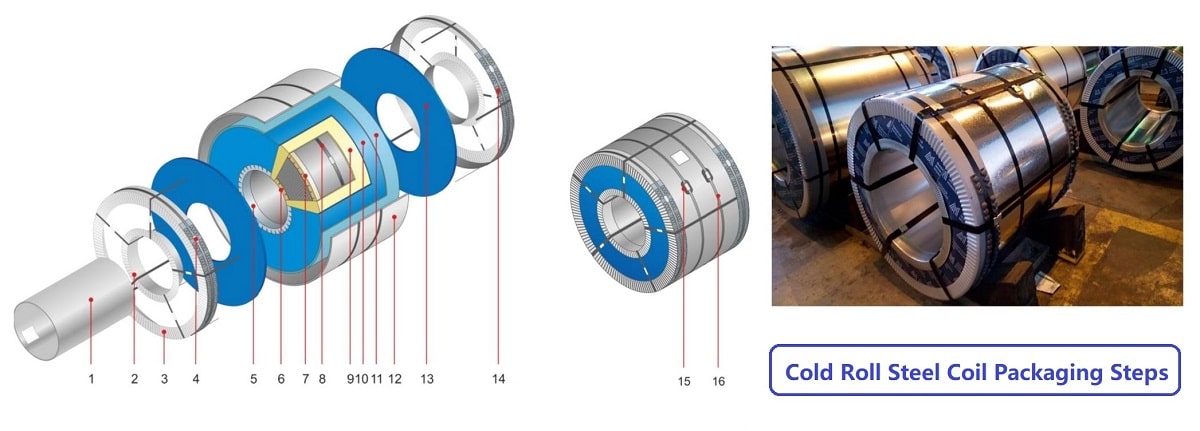

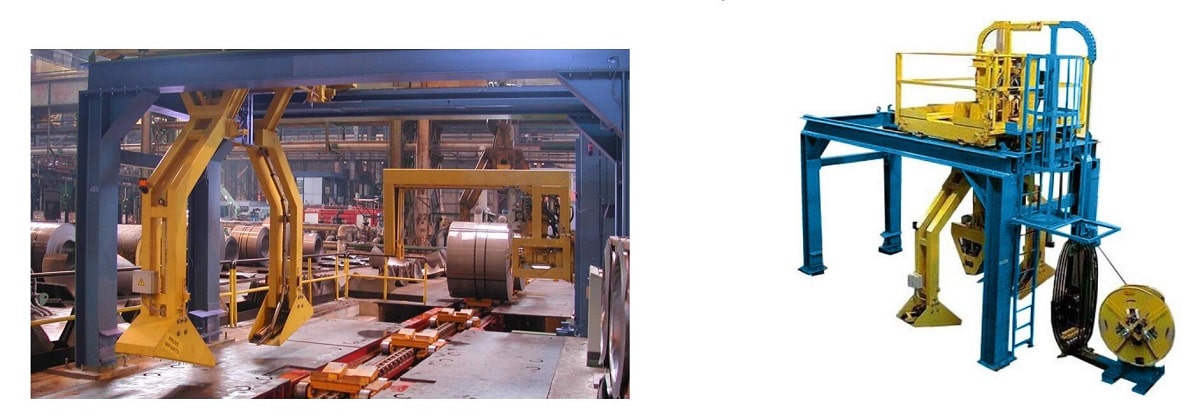

Automatic Packing LineSteel Coil Strapping & Packing Line

This document details the equipment specifications required for the Cold Roll Steel Coil Packaging Line as part of the automation project. FHOPE will handle on-site installation and provide technical support. As the manufacturer, the packaging machines provided will be complete, except for components specified as ‘Supplied by Others’ in this document. The equipment will incorporate the latest and most reliable state-of-the-art technology in its design, automation, and component choices. Efforts have been made to ensure that the equipment is energy-efficient. The line is designed to operate fully automatically, minimizing the need for manual intervention as much as possible. The packaging line will be directly integrated with the production line. Additionally, the system includes a transportation method for moving coils from the cold roll production line and the Automatic Storage and Retrieval System (ASRS) to the Packaging line.