Technical Specifications and Performance

We take full responsibility for the complete design of the equipment, ensuring its integrity, and maintaining the accuracy and completeness of all related documents. Our designs adhere to the Metric system and comply with ISO standards. All bearings conform to international standards.

- Solid and Durable Structure: Built to last under rigorous conditions.

- Designed for Wire Coil Compacting: Customized for use with a rack.

- Soft Start and Stop Mechanism: Ensures gentle operational handling.

- Hydraulic Compaction: Delivers powerful and consistent compaction.

- Safe and Stable Transmission: Utilizes a special mechanism for enhanced safety.

- Conveyor System: Facilitates easy loading and unloading.

- Enhanced Safety Features: Includes multiple limit protections.

- Automatic Shutdown: Increases safety by stopping automatically.

- Manual Strapping Position: Dedicated area for manual strapping.

- Dual Back Pressure Technology: Ensures smooth transitions during shifts in gravity.

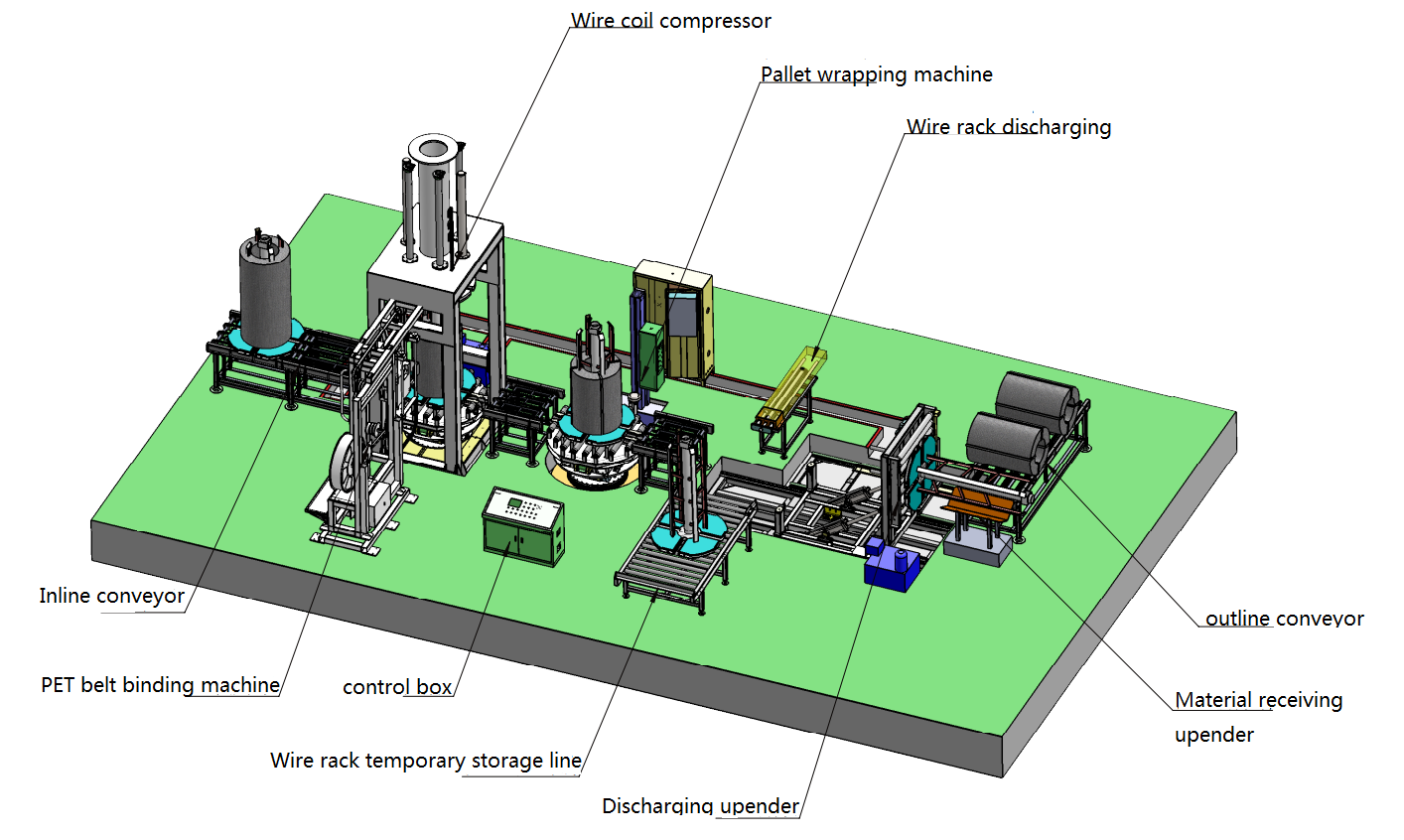

Operation Process

a. Conveying: Transports the wire with rack to the compaction position.

b. Placement: Conveyor lowers to position the wire rack for compaction.

c. Automatic Compaction: Activates compaction process.

d. Transition: Raises the conveyor and moves the compacted coil to the next station.

Main Technical Parameters

Strapping Material

- Strap Width: 19mm

- Strap Thickness: Available in 1.00mm and 1.27mm

- Strap Type: Polyester

- Strap Quality: Options include smooth or high-quality polyester strap.

This structured format provides a clear and organized overview of the machine's capabilities, operational steps, and key technical parameters, aligning with industry standards for efficiency and safety.