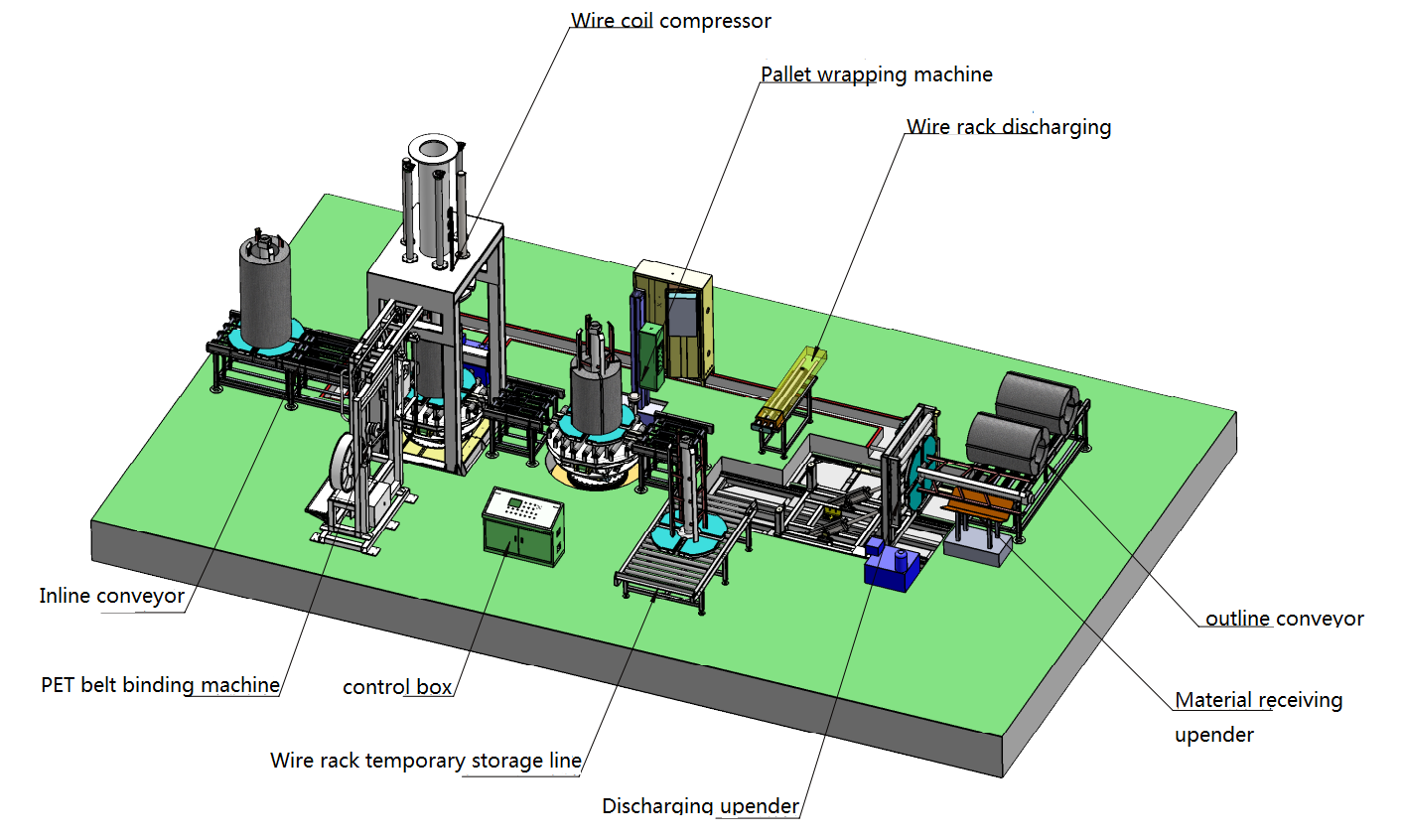

Automatic Packing LineAutomatic wire coil compressing and strapping machine packing line

The Automatic Strapping Machine is capable of executing multiple straps at various positions. The wire coil, along with its basket, is positioned on a table where the compactor system compresses the coil onto the spool. The system’s settings are adjustable to handle different materials, facilitated by inverters. The design of the line is structured to manage up to 8 coils per hour, each with its corresponding basket. Additionally, each coil will receive four radial straps, a specification determined by the customer, ensuring that the line meets the provided requirements.