Small Part Assembly: The Future of Industrial Automation Robots

In today’s fast-paced manufacturing industry, automation plays a crucial role in maximizing productivity and efficiency. One remarkable example of this is the use of Industrial Automation Robots, specifically FANUC’s LR Mate 200iC robots equipped with 2D iRVision. These robots have revolutionized small part assembly, making it faster, more accurate, and highly reliable.

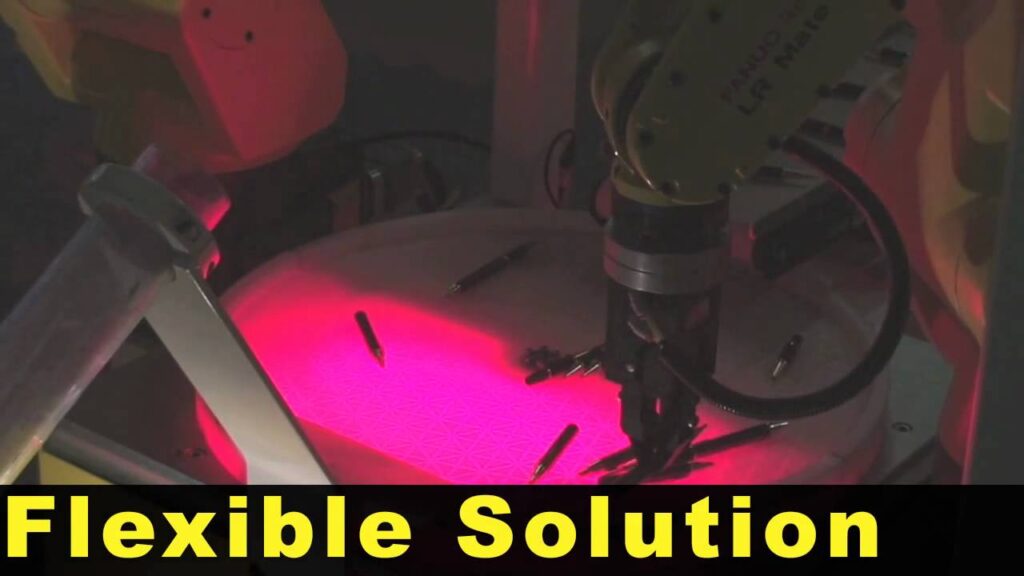

The LR Mate 200iC robots are designed to handle various assembly tasks with utmost precision. Equipped with state-of-the-art 2D iRVision, these robots have the ability to “see” and accurately locate even the smallest parts, ensuring flawless assembly. This advanced vision technology enables the robots to adapt to different part variations and orientations, making them highly versatile and efficient.

The incorporation of Industrial Automation Robots like the LR Mate 200iC robots in small part assembly has proven to be a game-changer for industries. Previously, manual assembly processes were not only time-consuming but also prone to errors. With the introduction of these robots, companies are able to achieve higher production rates as well as consistent quality output.

One of the key advantages of using LR Mate 200iC robots for small part assembly is their impressive speed and agility. These robots can perform assembly tasks at a much faster rate compared to their human counterparts. As a result, companies experience reduced production cycle times, leading to higher output and increased profitability.

Moreover, the LR Mate 200iC robots are designed to work collaboratively with human operators. With built-in sensors and safety features, they can detect the presence of humans in their working area, ensuring a safe working environment. This collaboration between humans and robots not only improves productivity but also reduces the risk of workplace accidents.

The use of Industrial Automation Robots like the LR Mate 200iC robots also brings about cost savings for companies. While the initial investment may seem significant, the long-term benefits outweigh the costs. These robots have a high return on investment as they eliminate the need for manual labor, reducing labor costs and minimizing human errors. Additionally, the robots have a longer operational lifespan and require minimal maintenance, further reducing operational expenses.

Furthermore, the LR Mate 200iC robots can be easily programmed and reprogrammed to accommodate different assembly tasks. This flexibility allows companies to adapt quickly to changing production needs without incurring additional expenses. With their user-friendly interface, the robots can be programmed by technical engineers or trained operators, eliminating the need for specialized programming skills.

The application of Industrial Automation Robots in small part assembly is not limited to a specific industry. From automotive to electronics, these robots have proven their worth in various sectors. They have the capability to handle diverse assembly processes, such as inserting pins, connectors, or performing delicate soldering operations. This versatility makes them an ideal choice for companies looking to enhance their assembly processes across different product lines.

Looking ahead, the future of small part assembly seems promising with the continuous advancements in Industrial Automation Robotics. Manufacturers are constantly pushing boundaries to develop smarter robots with enhanced capabilities. With the integration of artificial intelligence and machine learning, we can expect even more sophisticated robots capable of self-learning and adaptation.

In conclusion, the use of Industrial Automation Robots, such as the LR Mate 200iC robots equipped with 2D iRVision, has transformed small part assembly in the manufacturing industry. These robots offer unparalleled speed, accuracy, and versatility, resulting in increased productivity and consistent quality output. As the automation technology continues to evolve, we can anticipate further advancements that will revolutionize the way we approach small part assembly. Industrial Automation Robotics is undoubtedly paving the way for a more efficient and productive future.

Industrial Robot

“Enhancing Industrial Assembly Efficiency with LR Mate 200iC Small Part Robots”