Key Features:

- Utilizes top-tier brands for major components, ensuring exceptional quality.

- Incorporates a Programmable Logic Controller (PLC) for enhanced control.

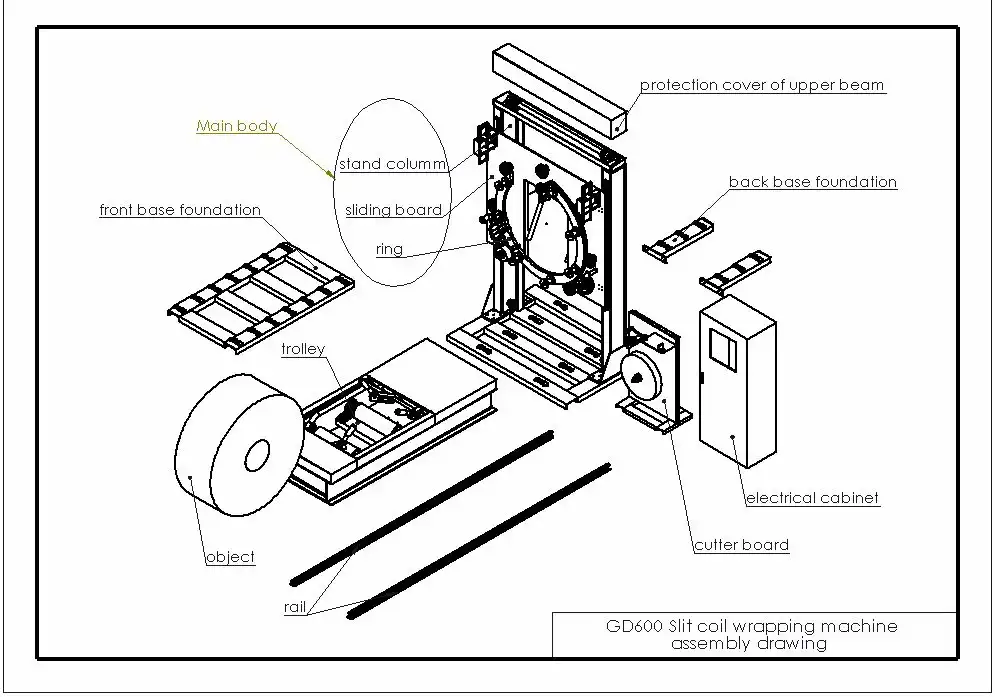

- Features a trolley system for the convenient, safe, and reliable loading and unloading of coils.

- The height of the ring board is motor-adjustable to accommodate various coil outer diameters.

- Capable of using two different types of wrapping materials simultaneously.

- Special tension control system adjusts wrapping film tension for optimal packaging across all coil sizes.

- Safety guard installed around the ring part to ensure secure operation.

- Overlapping rate is customizable via a converter to meet specific requirements.

- Equipped with soft start and soft stop functions to enhance operational safety.

- Includes a function to reset the packing position.

- Features overloading protection to prevent equipment damage.

- Combines both electric and mechanical limitations for enhanced operational safety.

- Guardrails on the moving parts to ensure operator safety.

- Ring and roller speeds are adjustable through a converter for precise control.

- An independent electrical control cabinet simplifies operation and maintenance.

- Adjustable friction between the wheel and ring facilitates smooth ring rotation.

- Long-lasting PU wheels designed for extended use.

- Allows for the setting of packaging times on the control panel for automatic cessation.

- Reinforced ring and structure provide durability and stability for prolonged usage.

- Equipped with an automatic alarm indicator for immediate issue notification.

Optional Parts:

a. Advanced Film Tension Control System

This system ensures uniform packing tension across both small and large wire coils, achieving a tight and secure packaging finish.

b. Automatic Material Cutter

Features an automatic material feeding and cutting mechanism, which eliminates the need for manual tying and cutting of materials. This cutter is specially designed to handle both stretch film and paper simultaneously.

c. Interlock System

Incorporates a fortress interlock for the rotating parts to enhance safety during operation.

d. Human-Machine Interface (HMI)

An essential component for controlling the machine, the HMI facilitates the automation of cutting and other processes, making it integral for streamlined operations.